These days, the construction industry is facing a lot of challenges. First, there is a shortage of construction labor as the younger generation prefers to work behind a desk. Second, commodities prices are rising, and the cost of construction materials are naturally following the trend. Finally, competition is high due to the building boom and a lot of new entrants to the market. Unfortunately, these challenges are all leading to the same thing: shrinking profit margins.

With slim profit margins, it isn’t surprising that a lot of construction businesses are failing. Being in business is difficult, and all kinds of new businesses have a high risk of failure in the first five years. With all of this in mind, how do we avoid being another statistic? By increasing profit margins.

Here are 9 ways to do this. They are divided into 2 categories:

- Control costs

- Increase revenue

For best results, you’ll need to do both.

Table of Contents

ToggleControl Costs

There’s one thing about controlling costs: some things won’t change, like the pricing pressures on labor and materials. However, you can learn to be more efficient.

1. Control your overhead

Your first step in any cost control program is to keep your overhead under control. Now, this doesn’t mean you need to do everything yourself. In fact, keeping costs TOO low can backfire if it results in your business not running efficiently. On the other hand, having too much overhead makes it harder to be profitable in a competitive environment.

What’s the balance? Typically, you want enough administrative employees to keep everyone busy all day for full-time employees. Part time employees should be busy the whole time they’re at work, except agreed-on breaks. Likewise, you want to make sure that your office or workshop is the right size and right price. Don’t pay too much for real estate. Instead, make a selection that’s affordable.

Finally, know when to rent or lease equipment, and when to buy it. If you don’t use something very often, then a rental is probably the way to go. You’ll need to pay for the days you’re using it, and certain consumables like fuel. But the maintenance and repairs are the owner’s problem. Likewise, something which is used on every job (or close to it) can be leased or purchased. Don’t waste money on purchases that aren’t necessary, as this just sucks money out of your business.

2. Outsource when appropriate

This one goes with keeping overhead under control. There are a lot of critical tasks that don’t have to be done in-house. One example is payroll and bookkeeping. In most towns, you can find a business services firm that can do these tasks for you. Typically, they’ll also handle tax returns and invoicing. Another way you can outsource is marketing. It’s easy to hire a marketing firm that will help bring in more business at a per-hour or per-campaign cost.

Why outsource? It reduces payroll costs, for one thing. You don’t have to hire a “jack of all trades” employee that keeps the books, does marketing, and whatever else comes up over the course of a day. While it’s good to have someone who can answer the phones, this could easily be you as the owner. With outsourcing, you only pay for what you need. Plus, the cost of having a specialist employee is paid as part of the outsourcing fees. You won’t have to worry about them as separate line items.

3. Use project management techniques

Part of controlling costs is knowing how much money you are spending on which projects, and at what point in the contract. With project management software, it’s easy to keep track of how many pieces of 2×4 lumber your team used on the shed. In addition, employee time cards, benefits, and sick time can be tracked and credited to the proper contract. This way, you aren’t just paying out money on a weekly basis. Instead, every dime of labor and unit of materials are accounted for.

You can also use project management software to see how well you’re doing with estimates and improve performance over time. It also allows you to identify waste and abuse, where they can be reduced or eliminated. Foremen can be held accountable, as well.

4. Waste not, want not

One of the big challenges of cost control in construction is waste. This includes extra materials that are ordered but not used, packaging disposal costs, and poor fabrication techniques. A certain amount of waste is inevitable, because not everything can be used. But excessive waste drives up materials and disposal costs.

Fortunately, there are several ways to make your company’s waste minimal. First, try to order only the materials you need. If minimum orders and package sizes make this impossible, try to spread the total out over more than one project. You can always use a few extra nails or pieces of plywood, so long as you store them for use when needed. Second, get your suppliers to use reusable containers for delivery whenever possible. This way, you can save the planet and avoid disposal costs. Third, keep usable scraps of materials so that they can be used for repairs, patches, and small jobs.

5. Manage productivity

Unfortunately, one of the big challenges in construction is employee productivity. One of the reasons for this is that construction companies aren’t used to tracking what employees are doing. This has resulted in many hours that are paid for, but not truly worked. To reduce this, insist that your crew doesn’t clock in until they’re actually working. Likewise, a 15 minute break really is 15 minutes long. Break and timekeeping rules do vary by state, so be sure to verify compliance.

At the same time, be sure to have production targets for everyone. While the occasional delay due to equipment breakdowns or late material deliveries is inevitable, you don’t want idled employees. For that reason, you need to set expectations for employees. One example would be telling employees that a porch needs to be built within a certain number of man hours. If you commit to a production schedule, hold your employees to it as much as possible.

Increase Revenue

Cost cutting, while important, can only get you so far. If you’re going to increase profitability over time, it’s important to increase revenue. This doesn’t mean simply keeping busy, it means increasing the amount you’re paid for each contract of a given size.

6. Be job selective

Not every job is worth bidding on, much less accepting, even if it’s in your niche. Why? Because there’s more than one type of customer out there. For instance, some of them are cheapskates. They’ll put a job out to bid, and expect the lowest price. Typically, they don’t even care if a quality job is done, just if the build will pass inspection. We normally recommend avoiding these jobs, because it’ll be hard to beat the competition while turning a profit.

Another kind of job to avoid is the one with a finicky customer. These are the ones who change their minds constantly, pay slowly, or cause drama on the job. While some project changes are normal, you don’t want customers with a long record of making unreasonable demands or changes too close to completion. High-maintenance clients erode your profit margins through increased costs and reduced productivity.

Instead, look for jobs where the client is more particular about who does the job. This means getting on bid lists where you must demonstrate qualifications and a record of success. In other words, seek the clients that want a quality job. They are willing to pay more money, allowing for better profits. Needing to qualify also reduces your competition and increases the chance of turning a bid into a contract.

7. Differentiate from the Competition

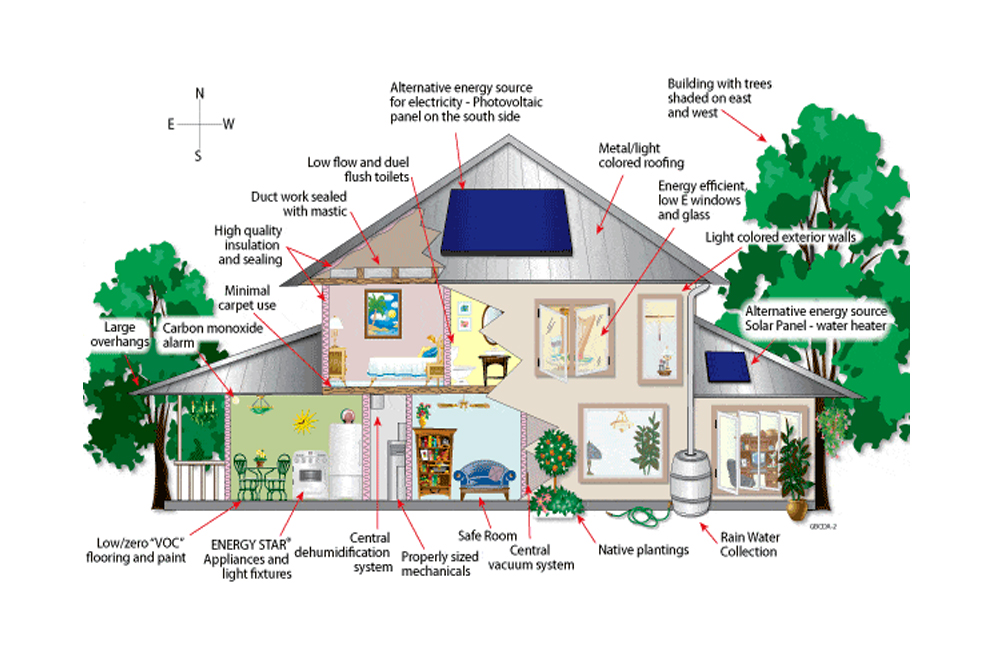

Do you really want to increase profits? Then become a specialist in a particular type of construction. We don’t mean commercial vs. residential, we mean carve out a particular niche. For instance, you might be really good at custom homebuilding. Or, you might prefer to construct energy efficient office buildings. Over time, you’ll get a nice portfolio of this type of project that can be shown to potential clients.

By differentiating, you can reduce the number of direct competitors. Almost anyone can repair existing structures or do a remodeling project.

However, not everyone is great at custom homes. These clients tend to have high expectations and be willing to pay for great results. Alternately, energy efficient construction is a niche that requires special skills and has higher margins. Find out what those shortage niches are in your area and get good at it. You’ll have less pricing pressure.

8. Bid for profit

Bidding for profit requires two basic skills: knowing your true costs, and understanding what the market will bear. First, there’s knowing your actual costs. Remember the project management system we talked about? With the actual expenses tracked, your cost numbers are more accurate than if you’re guesstimating based on what “seems reasonable.” You’ll know how efficient your crew is, how much lumber they use to frame the house, and what your overhead costs are. From here, adding profit margins are easy.

At the same time, you need to know how much you can reasonably charge for a job. Not only does the amount of competition play into this, but there are market norms in every area. Increasing profit margins is wonderful, but if you jack prices up too much then it can backfire. Part of bidding for profit is knowing what the balance is.

Finally, bidding for profit can mean outsourcing the estimating process. There are specialist firms that do little besides estimating and takeoffs. You send them the plans, and they’ll give you a bid for a flat fee. Then, you can buy a takeoff from them if the bid is successful. This way, you can benefit from a highly experienced estimator without the overhead of hiring your own. And, it frees up your time to do other things. More accurate estimates drives up profit.

9. Seek repeat business and referrals.

Finally, becoming more profitable involves repeat clients and client referrals. Happy clients will often come back when they need something else. That something else for residential clients might be putting up a shed or detached garage, adding a deck, and more. On commercial contracts, there might be another building that needs to be put up. Or, an expansion to the existing building might be necessary. The possibilities are endless. Bonus if your happy client needs a contractor regularly.

Likewise, referrals help build profit margins. We know of a homeowner who contracted with a particular roofer because her neighbor had it done and was pleased with the results. In this case, the main competitor wasn’t even given the chance to bid. Likewise, someone who had a custom home built and is happy with how it worked out might encourage a future neighbor to choose the same contractor. The beauty of referrals is that you typically don’t have to compete for the business. Give the potential client a fair deal, and the contract is yours to lose.

Increasing profit margins in construction isn’t always easy. Rising costs and stiff competition often make it feel like you can’t get ahead. Fortunately, there are many effective strategies to reduce costs and increase bid prices. Together, these two sets of techniques will increase the profitability of your business. Keep in mind, professional advice from attorneys and accountants can sometimes be helpful. Either way, getting off the hamster wheel of working for almost nothing is essential to the survival of your business.